Introduction

Handling high-value, fragile, or sensitive items requires more than standard warehousing. From luxury electronics and medical devices to precision electronic components, even minor mishandling can lead to significant financial losses. White glove warehouse services go beyond conventional storage and delivery by providing specialized care, tailored handling, and full accountability for every step of the supply chain.

As the Malaysian premium retail, healthcare, and IT sectors expand, businesses increasingly demand secure, efficient, and technology-driven solutions. White glove services now play an important role in protecting high-value cargo, ensuring operational efficiency, and maintaining customer trust, particularly during peak seasons or complex delivery projects.

Behind the Scenes of White Glove Warehousing

White glove logistics begins long before delivery. Inside the warehouse, every process is optimized to safeguard valuable cargo:

- Specialized Storage Solutions

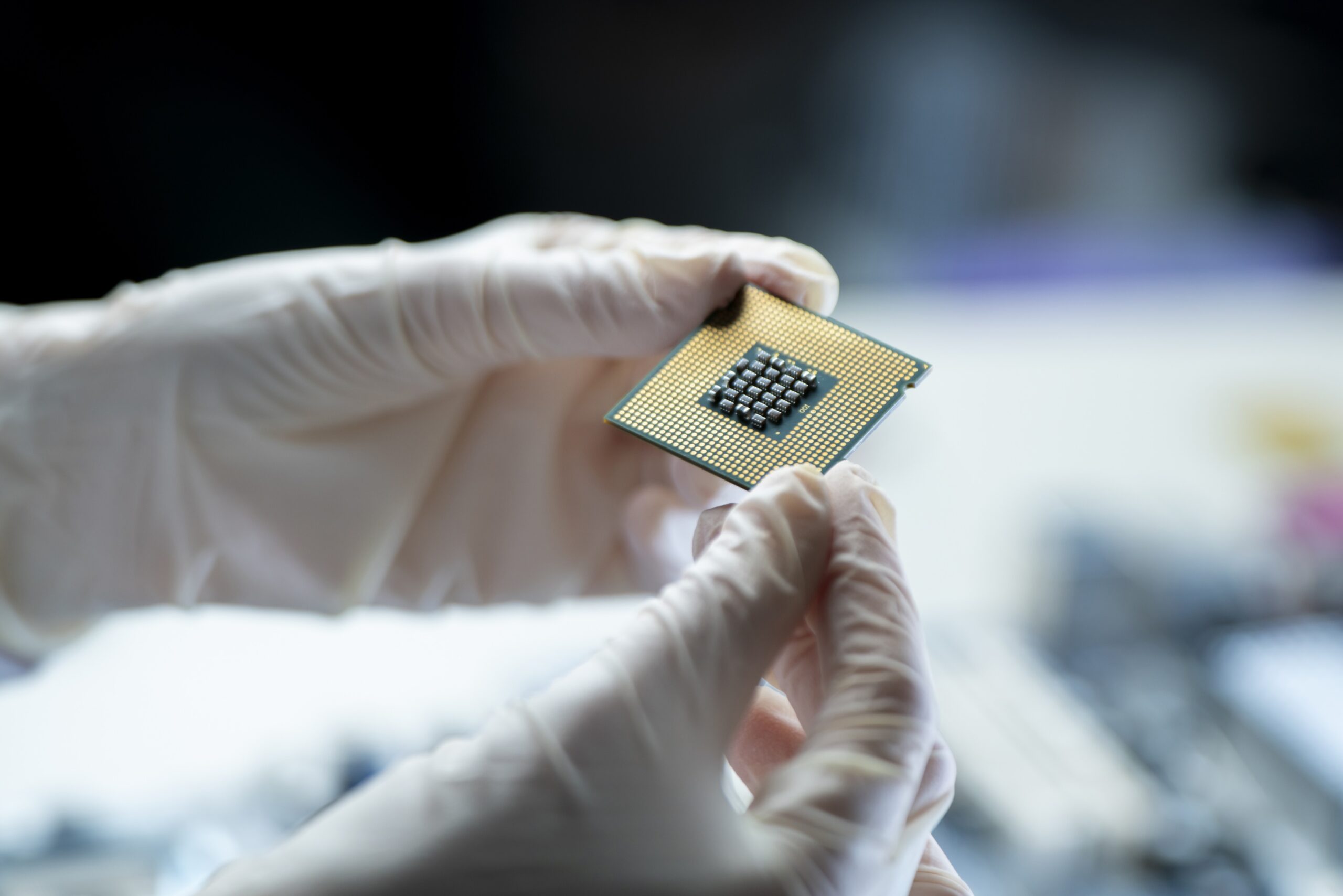

High-value items are stored in modular, climate-controlled zones with strict access protocols (as required). Certain sensitive cargo requires ESD-safe handling areas and controlled humidity levels to prevent functional degradation.

- Advanced Handling & Training

Warehouse teams receive hands-on training to manage delicate, oversized, temperature-sensitive, or electrostatically sensitive items. Every movement, from receiving to picking, follows clearly defined standard operating procedures.

- Technology Integration

Real-time scanning, condition monitoring, and inventory management systems track items continuously. Sensors detect shocks, humidity changes, or temperature deviations, which is critical for cargo with tight tolerance thresholds.

- Efficiency Without Compromise

Optimized layouts, batch processing of similar shipments, and workflow automation allow warehouses to handle high-value cargo quickly while maintaining accuracy and security.

Example: A distributor handling high-value electronic components, including microchips, benefits from EFL 3PL’s secure storage zones, real-time inventory updates, and careful handling, reducing the risk of damage while ensuring fast order fulfillment.

Protecting High-Value Cargo from Storage to Delivery

White glove services are about end-to-end protection. Beyond the warehouse, logistics operations are designed to minimize risk at every stage:

- Custom Packaging & Shock Absorption

Fragile or expensive items are packed with bespoke materials to protect against shocks, moisture, vibration, and static exposure during transit.

- Secure Transport & Delivery

Vehicles equipped with tracking systems and, where needed, climate control ensure items maintain optimal conditions until arrival.

- Condition Monitoring

Temperature, humidity, and impact sensors alert teams if anomalies occur, helping protect cargo where minor deviations can cause functional issues.

- Real-Time Visibility

Clients can track shipments at every stage, enabling better planning, SLA management, and peace of mind.

Industry Impact: Malaysia’s medical device market, valued at USD 4.04 billion in 2024 and projected to reach USD 13.57 billion by 2030 (GlobeNewswire, 2025), relies heavily on white glove services to maintain strict handling standards and comply with regulatory requirements.

Industries That Benefit Most

White glove warehouse services are increasingly critical across several Malaysian sectors:

- Healthcare & Pharmaceuticals

Medical devices, lab instruments, and temperature-sensitive drugs demand precise handling. (MIDA Report, 2024).

- Luxury Retail & Electronics

High-end watches, smartphones, or fashion items require secure storage, careful packaging, and safe delivery.

- IT & Data Centers

Servers, robotics, networking hardware, and other precision electronic equipment require careful unpacking, installation, and monitoring.

- Art & Exhibitions

Fine art or collectibles require specialized handling, installation, and protection from environmental hazards.

By offering customize solutions for each sector, white glove services ensure high-value items reach clients intact, on time, and in optimal condition.

EFL 3PL: Your White Glove Warehouse Partner

EFL 3PL goes beyond standard warehousing to provide specialized handling for high-value cargo. From receipt to final delivery, every step is monitored to prevent damage or loss. Modular storage layouts and tailored picking processes ensure fragile and sensitive items are managed safely, while cross-trained teams adapt seamlessly to varying cargo types and peak-season surges.

Modular storage layouts and tailored picking processes also support cargo with strict handling, environmental, and tolerance requirements—without compromising operational efficiency.

Key features include:

- Real-time condition monitoring

Temperature, humidity, and shock sensors alert teams instantly to prevent issues.

- Automated workflows

Streamlined processes reduce errors and improve turnaround times.

- Custom storage organization

Items are arranged based on fragility, value, or environmental needs.

Conclusion

In Malaysia’s competitive logistics market, white glove warehouse services are no longer optional for high-value or sensitive cargo. By implementing specialized storage, trained staff, technology-driven monitoring, and end-to-end protection, businesses can reduce damage, increase reliability, and enhance customer trust. With EFL 3PL, companies gain a partner capable of managing premium cargo efficiently, safely, and professionally, turning high-value deliveries into a competitive advantage.

Partner with EFL 3PL to protect and move your high-value cargo with confidence.